As one of the important technical paths for future energy transformation, hydrogen fuel cells are gradually moving from cutting-edge exploration to practical application, and are expected to achieve more extensive commercial deployment between 2025 and 2035. At present, many global companies such as Hyundai, Honda, and Ballard Power Systems are fully committed to promoting the research and development of hydrogen fuel cells and actively planning their mass production plans, and the competition in the industry is becoming increasingly fierce. Hydrogen fuel cells have significant advantages over traditional fuel engines and some other new energy technologies in terms of energy conversion efficiency, cruising range, and environmental performance. However, problems such as high costs and lagging infrastructure construction are still the main obstacles to their large-scale popularization.

Customized hydrogen fuel cell system: a potential new star in a diversified market

Compared with traditional energy systems, hydrogen fuel cells can not only achieve efficient energy conversion, directly convert chemical energy into electrical energy, and reduce energy loss, but also only produce water during operation, with almost zero emissions, greatly reducing pollution to the environment. They have shown extremely broad application prospects in many fields such as transportation, distributed power generation, and portable power. In addition to the highly anticipated transportation field, hydrogen fuel cells also have great development potential in the customized energy system market. From a technical perspective, customized hydrogen fuel cell systems are widely used in scenarios such as backup power supplies for data centers, power supply facilities in remote areas, special operation vehicles, and high-end ships that have extremely high requirements for energy supply stability, efficiency, and environmental protection. Hydrogen fuel cells can output electricity continuously and stably, are not affected by power grid fluctuations, and do not emit harmful gases, significantly improving the reliability and cleanliness of energy supply.

Hydrogen fuel cell core components: key technical breakthroughs

Catalyst and membrane electrode R&D strength

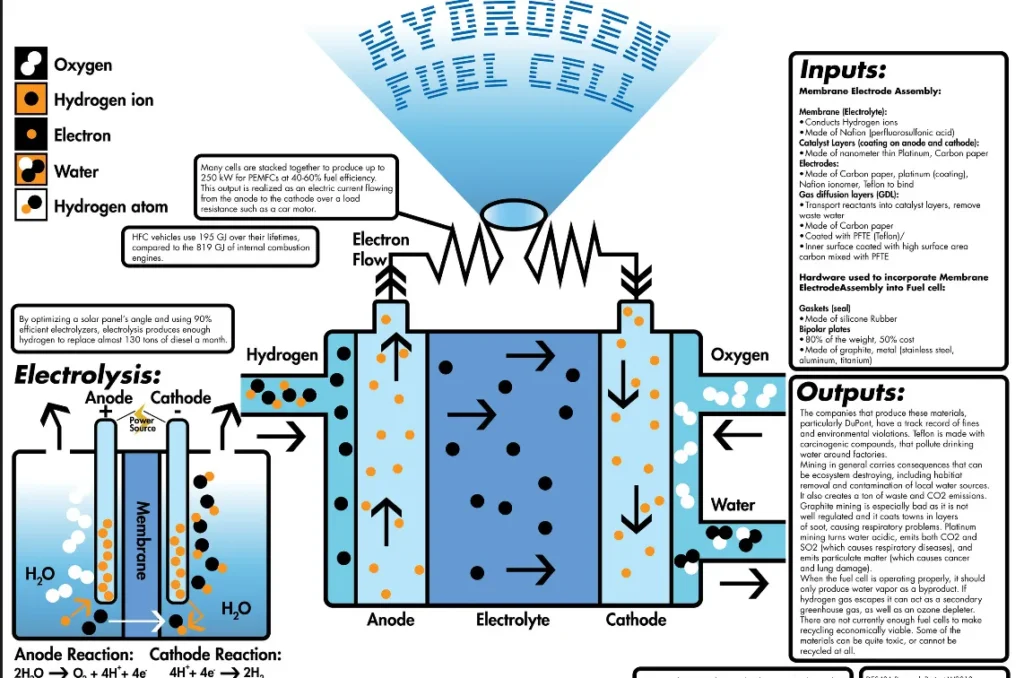

The performance of hydrogen fuel cells depends largely on the materials and design of core components. Companies need to have strong R&D capabilities to develop high-performance catalysts and membrane electrode materials. For example, breakthroughs in seeking efficient and low-cost alternatives to platinum-based catalysts, or developing membrane electrodes with higher proton conductivity and stability, just like Ballard Power Systems’ continuous exploration of non-platinum catalysts and advanced membrane electrode technologies.

In the battery stack design and integration process, companies need to carefully design a reasonable battery stack structure to effectively solve key problems such as gas diffusion, hydrothermal management, and power density improvement. In addition, the commercial application of hydrogen fuel cells also faces technical challenges such as catalyst poisoning and membrane electrode durability. Companies must overcome these problems through innovative material formulations and optimized preparation processes.

Customization to meet customers’ diverse needs

Customers of customized hydrogen fuel cell systems usually have very clear and special performance requirements. Hydrogen fuel cell companies need to carry out precise customized design and production based on these needs to ensure that the fuel cell system can perfectly adapt to various application scenarios. The high energy conversion efficiency of hydrogen fuel cells can provide long-term and highly stable power support for data center backup power supply, ensuring the continuous operation of data centers.

For distributed power generation systems, efficient energy conversion means that more electricity can be generated under the same hydrogen fuel input, thereby improving energy utilization efficiency. The zero-emission characteristics of hydrogen fuel cells during operation give them unique advantages in power supply in areas with strict environmental protection requirements, such as nature reserves and urban core areas.

In some special operating environments (such as high altitudes, low temperatures, etc.), hydrogen fuel cells show stronger adaptability than traditional energy systems, can work stably, and are suitable for special scenarios such as polar scientific research equipment and high-altitude base station power supply.

Customized production and manufacturing capabilities

The customized hydrogen fuel cell market usually requires design and production according to the personalized needs of specific customers. The modular design concept and strong flexibility of hydrogen fuel cells enable them to better meet various power, size and performance requirements. Suppliers need to have advanced manufacturing capabilities that can accurately match these needs.

In terms of process innovation and optimization, the production of hydrogen fuel cells is quite different from traditional energy equipment manufacturing. Enterprises need to develop a series of unique new processes such as catalyst coating, membrane electrode assembly, and battery stack sealing, and continue to optimize them to improve production efficiency and product quality. For example, some companies have successfully developed automated membrane electrode production equipment, which effectively improved production efficiency and product consistency.

In terms of quality control, companies must build a strict and complete quality control system to ensure that the entire process from raw material procurement, component manufacturing to system integration and product testing can maintain a high degree of consistency and stability, and effectively meet various stringent performance and safety standards.

Cost and large-scale production dilemma

The current actual situation shows that the production cost of hydrogen fuel cells is still high, especially in terms of raw materials and key components. For example, platinum, a common catalyst material, is expensive and scarce. Although alternative materials for platinum have been explored, progress has been relatively slow. At the same time, high-performance membrane electrode materials are also expensive. In addition, the production process of hydrogen fuel cells is complex and has extremely high requirements for production equipment and environment. For example, the preparation of membrane electrodes requires high-precision coating equipment and strict environmental control, which undoubtedly increases equipment investment and operating costs. It is estimated that the current cost of hydrogen fuel cell systems is about several times that of traditional fuel engine systems.

These technical and cost bottlenecks have seriously restricted the large-scale production of hydrogen fuel cells, thereby delaying their market promotion process. Although some companies plan to achieve large-scale mass production of hydrogen fuel cells in the next few years, a lot of technical verification and optimization work is still needed to truly achieve full commercialization. Experts predict that even by 2035, although there may be some technological breakthroughs that make large-scale application of hydrogen fuel cells possible, it may take longer, perhaps about 20-30 years, to completely replace traditional fuel engines and become a mainstream energy technology. By then, as the technology matures and the scale effect emerges, the cost is expected to be greatly reduced to a level comparable to or even lower than that of traditional energy systems, thus bringing more development opportunities to the customized hydrogen fuel cell market.

In high-end customized markets (such as high-end yachts and aerospace fields) that are relatively less sensitive to cost and pay more attention to energy efficiency and environmental performance, hydrogen fuel cells are very likely to be the first to achieve commercial application.

Supply chain and industry collaboration

The large-scale production and widespread application of hydrogen fuel cells cannot be separated from the close collaboration of all links in the entire supply chain, including raw material suppliers, fuel cell manufacturers, system integrators, and equipment manufacturers. At present, in the field of hydrogen fuel cells, the United States, Japan, and some European countries are at the forefront of technology research and development and industrial layout, and actively promote the construction and improvement of local industrial chains. However, global industrial collaboration still needs to be further strengthened. Customers in the customized hydrogen fuel cell market have extremely high requirements for the stability and reliability of the supply chain. The development of the hydrogen fuel cell industry will strongly promote in-depth collaboration across the industry and improve the stability and operating efficiency of the entire supply chain.

Conclusion

In order to promote hydrogen fuel cell technology from the laboratory to large-scale commercial applications, the focus of research and development must gradually shift from simply improving the performance of a single fuel cell to optimizing the integration and operation of the entire fuel cell system. This means not only focusing on improving the power density, conversion efficiency and durability of a single cell, but also ensuring that each component can work together efficiently to form a stable and reliable energy supply system. System-level factors such as battery management systems, thermal management systems, and overall structural optimization of the system have now become the key to influencing the application of hydrogen fuel cells. They are directly related to the safety, stability and efficiency of energy supply. By focusing on these system-level optimizations, manufacturers are expected to provide better quality and more reliable energy solutions for large-scale application scenarios such as transportation and distributed power generation.

Another key challenge that needs to be addressed is to effectively reduce costs and ensure the scalability of production while expanding production scale. The industry is actively exploring more efficient and low-cost production processes and developing product designs with good scalability to achieve the dual goals of reducing costs and ensuring performance.

Hydrogen fuel cells not only show great development potential in the field of transportation, but also have broad prospects in the customized energy system market. However, its commercial success ultimately depends on the comprehensive inspection and recognition of the market. Enterprises must continue to exert efforts in R&D innovation, production and manufacturing, quality control and cost control, and continuously optimize and improve to fully meet the diverse and personalized needs of customized hydrogen fuel cell users. For these users, the high energy conversion efficiency, excellent environmental performance and flexible customization advantages of hydrogen fuel cells will provide them with highly competitive energy solutions, which will effectively promote the rapid development and transformation of related industries.